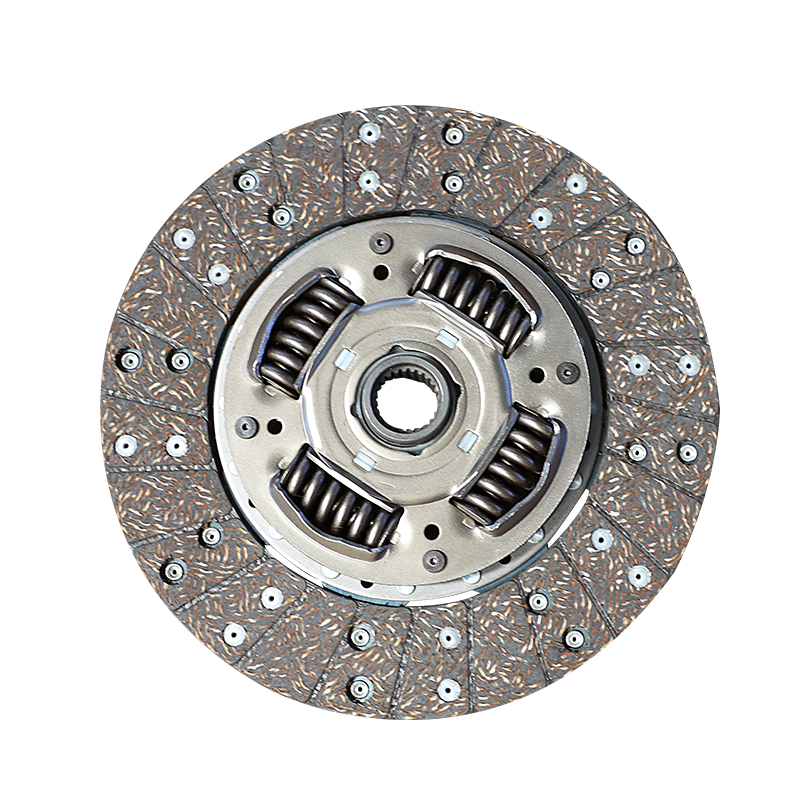

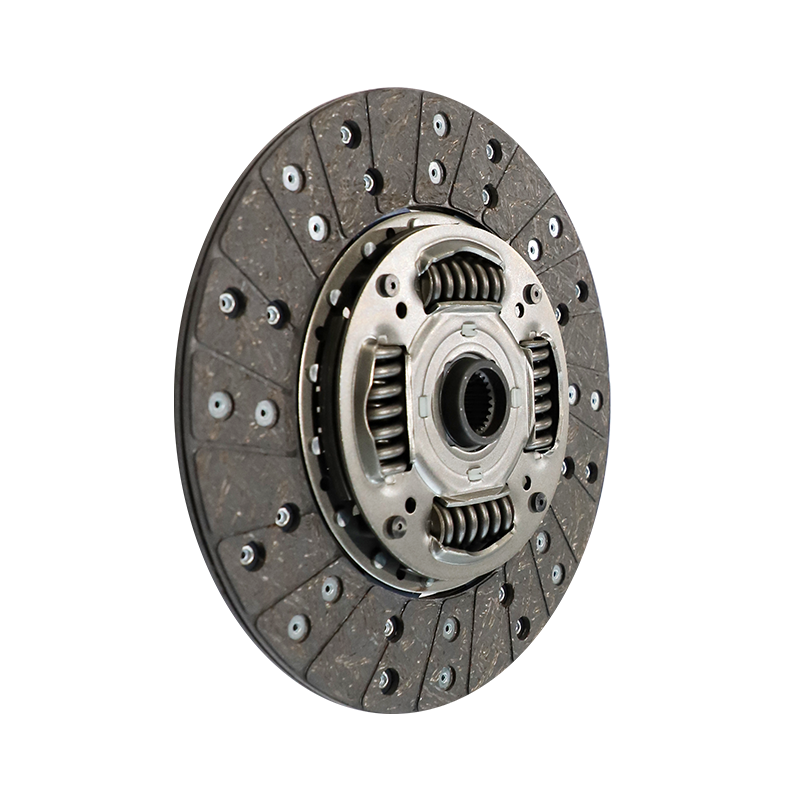

Famous Best Mack Clutch Suppliers – Factory Direct Sale Clutch Driven Plate Light Clutch Automobile Clutch 80076 – Feiying

Famous Best Mack Clutch Suppliers – Factory Direct Sale Clutch Driven Plate Light Clutch Automobile Clutch 80076 – Feiying Detail:

Detail

New material testing items

It has national-level friction material product quality testing capabilities. The collection and management of big data is carried out by means of technology such as intelligence and informatization.

① Explore the overall adaptability of materials and the relationship between product PH value and the environment from the perspective of material PH.

② Control the material fineness standard and stability, and explore the influence of material fineness on brake wear.

③ Using a microscope to detect the length of the fiber material to control the influence of the fiber length on the strength of the product.

Specification

Clutch Disc

100% Crucial Dimension, Crack Detection

Complete Models for Different Vehicles

Tens of Different formulation to satisfied to different market

|

No. |

Specification |

|

80010 |

430×260-10×52.3 |

|

80042 |

430X240-24X50 |

|

80047 |

308X191-10X38.4 |

|

80076 |

255X160-24X25.6 |

|

No. |

Specification |

mounting holes |

positioning hole |

|

80010 |

430X240 |

12XΦ11 |

— |

|

80042 |

420X220 |

12XΦ11 |

— |

|

80047 |

275X170 |

6XΦ9 |

3XΦ6 |

|

80076 |

300X190 |

10XΦ10.7 |

2XΦ10 |

Model Table

|

Category |

No. |

Applicable models |

|

Clutch disc |

80010 |

Adaptation: Shaanxi Automobile Delong*6000 and other 500-580 horsepower |

|

80042 |

Adaptation: Dongfeng Tianlong flagship (small plate), etc., 310-500 horsepower | |

|

80047 |

Adaptation: Foton, Omark and other high-end light trucks | |

|

80076 |

Adaptation: Foton, JAC high-end light trucks | |

|

Clutch pressure plate |

90004 |

Adaptation: Dongfeng, Foton, Sinotruk, etc. 310-520 hp (Universal) |

|

90021 |

Jinlong, Yutong and other buses, XCMG, Weichai, Deutz, etc. | |

|

90044 |

Adaptation: 3 ton forklift (Forklift) | |

|

90069 |

Adaptation: Foton, JAC and other high-end light trucks | |

|

Drum brake pads |

4551 |

trailer |

|

4705 |

trailer | |

|

19032 |

BPW | |

|

19094 |

BPW | |

|

19246 |

Sinotruk | |

|

19487 |

North Benz | |

|

19488 |

North Benz | |

|

19581 |

After Dronman | |

|

19582 |

After Dronman | |

|

Disc brake pads |

5200 |

— |

|

5300 |

— | |

|

29087 |

North Benz, Scania, Shaanxi Heavy Truck | |

|

29228 |

BPW | |

|

DA05 |

Delong Bridge, Auman ETX | |

|

We have more than 2000 SKUs |

||

1. Annual production of 35 million pieces

2. Advanced and perfect material formula and front-end quality inspection big data center

3. Possess ISO14001/IATF16949 quality certificate

OE standard, CCC certified

Classification

Clutch Disc

Using the original standard clutch special friction material, it can withstand the harsh environment and prolong the production.

Product life.

The specially designed wave spring plate can prolong the clutch engagement time and make the Smooth start.

Excellent Type

Clutch driven disc assembly (excellent type) Imported aramid fiber, glass fiber and copper wire are used to form the skeleton material, high temperature resistant resin and rubber are used as adhesives, combined with imported friction performance regulators, high-quality fillers, and advanced technology. produced. The product has smooth engagement, high temperature resistance, friction resistance, and stable friction coefficient. It is suitable for various types of vehicles, especially for medium and heavy commercial vehicles.

Wear-Resistant Type

Clutch driven disc assembly (wear-resistant type) The skeleton material is composed of high-quality glass fiber, acrylic fiber and high-component red copper wire, high-temperature resin and rubber are used as binders, and high-quality imported friction performance regulators and high-quality fillers are used. And so on, with advanced technology for production. It has excellent joint smoothness and wear resistance, stable friction coefficient, and is suitable for various models.

Product detail pictures:

Related Product Guide:

All we do is always involved with our tenet " Consumer initial, Trust first, devoting within the food stuff packaging and environmental defense for Famous Best Mack Clutch Suppliers – Factory Direct Sale Clutch Driven Plate Light Clutch Automobile Clutch 80076 – Feiying , The product will supply to all over the world, such as: Greece, Belgium, Kazakhstan, Our company will adhere to "Quality first, , perfection forever, people-oriented , technology innovation"business philosophy. Hard work to keep making progress, innovation in the industry, make every effort to first-class enterprise. We try our best to build the scientific management model, to learn abundant professional knowledge, to develop advanced production equipment and production process , to create the first-call quality products, reasonable price , high quality of service , quick delivery , to give you create new value .

In China, we have purchased many times, this time is the most successful and most satisfactory, a sincere and realiable Chinese manufacturer!

![Discount Truck Parts Brake Pads Quotes – [Copy] Factory Hot Sale 5200 Brake Lining Manufacturing Brake Shoes Lining For Truck Part DT5300 – Feiying](http://cdn.globalso.com/toughprobrake/5200-5300-1.png)