Famous Best Truck Brake Shims Suppliers – Factory Price Truck BMW Brake Pad 29087 Brake-shoe Block Lining Auto Brake Pad System – Feiying

Famous Best Truck Brake Shims Suppliers – Factory Price Truck BMW Brake Pad 29087 Brake-shoe Block Lining Auto Brake Pad System – Feiying Detail:

Detail

Friction Coefficient

Is the friction coefficient of the brake pads the bigger the better?

Answer: No. The friction coefficient of the brake pad is designed according to the weight inertia of the car itself, which considers several technical indicators of speed, inertia, braking distance and comfort. The friction coefficient is generally marked in the market between 0.34 and 0.42. However, it is actually very simple to increase the friction coefficient, just increase the wear additive. The car factory’s criterion for judging the quality of the brake pad is not how big it is marked, but whether its friction coefficient remains stable under various extreme road conditions such as water spray, winding road, continuous sudden braking, etc. For many products that seem to be marked with a high coefficient of friction, their braking force will drop rapidly or even lose their braking ability in the above emergency situations. Such phenomena are not uncommon.

Specification

100% Crucial Dimension, Crack Detection

Complete Models for Different Vehicles

Tens of Different formulation to satisfied to different market

|

No. |

Specification |

PS. |

|

80010 |

217.5*107.5*31 |

Castings, spring bars and snaps are installed |

|

80042 |

247*109.5*30 |

9.0 thick, steel mesh steel back, with 4 spring bars |

|

80047 |

210.6*114*29.7 |

casting |

|

80076 |

220*91*30 |

Steel mesh steel back including 4 spring bars |

Model Table

|

Category |

No. |

Applicable models |

|

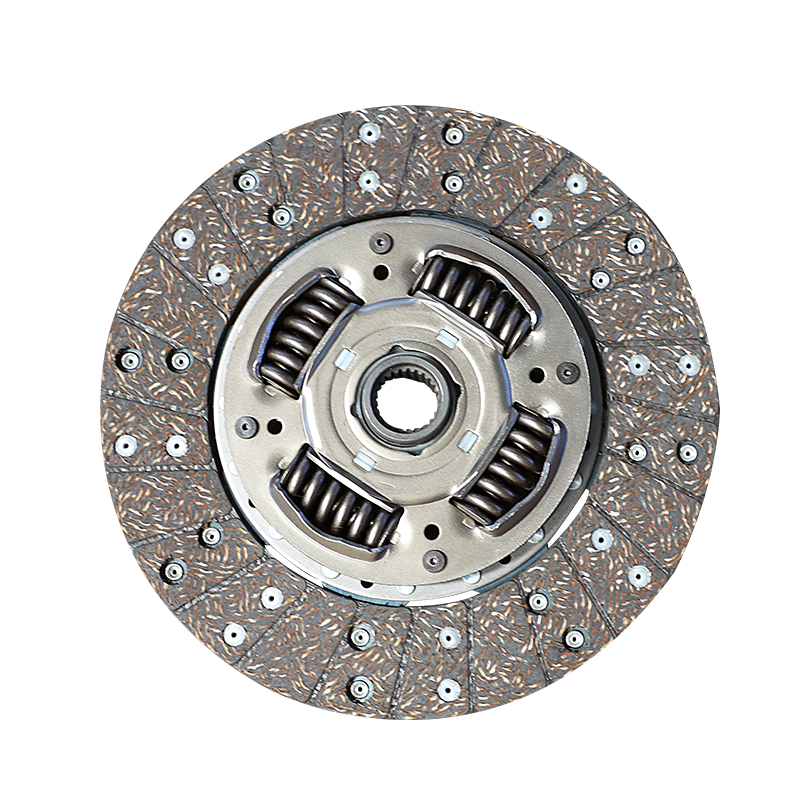

Clutch disc |

80010 |

Adaptation: Shaanxi Automobile Delong*6000 and other 500-580 horsepower |

|

80042 |

Adaptation: Dongfeng Tianlong flagship (small plate), etc., 310-500 horsepower | |

|

80047 |

Adaptation: Foton, Omark and other high-end light trucks | |

|

80076 |

Adaptation: Foton, JAC high-end light trucks | |

|

Clutch pressure plate |

90004 |

Adaptation: Dongfeng, Foton, Sinotruk, etc. 310-520 hp (Universal) |

|

90021 |

Jinlong, Yutong and other buses, XCMG, Weichai, Deutz, etc. | |

|

90044 |

Adaptation: 3 ton forklift (Forklift) | |

|

90069 |

Adaptation: Foton, JAC and other high-end light trucks | |

|

Drum brake pads |

4551 |

trailer |

|

4705 |

trailer | |

|

19032 |

BPW | |

|

19094 |

BPW | |

|

19246 |

Sinotruk | |

|

19487 |

North Benz | |

|

19488 |

North Benz | |

|

19581 |

After Dronman | |

|

19582 |

After Dronman | |

|

Disc brake pads |

5200 |

— |

|

5300 |

— | |

|

29087 |

North Benz, Scania, Shaanxi Heavy Truck | |

|

29228 |

BPW | |

|

DA05 |

Delong Bridge, Auman ETX | |

|

We have more than 2000 SKUs |

||

1. Annual production of 35 million pieces

2. Advanced and perfect material formula and front-end quality inspection big data center

3. Possess ISO14001/IATF16949 quality certificate; OE standard, CCC certified

Classification

Gifts Series

1. Environmentally friendly, non-asbestos and low metal formula

2. High friction coefficient, providing high braking force during use

3. Smooth braking

4. High cost performanceon various roads

High-end series

1. Environmentally friendly, non-asbestos and low metal formula

2. The friction coefficient is high and stable to ensure the safety of braking

3. Low wear rate and long service life

4. The friction surface is brushed with imported zebra-pattern glue, and the brake disc is cleaned during use to provide high initial grinding braking force

Product detail pictures:

Related Product Guide:

No matter new buyer or old purchaser, We believe in long expression and trusted relationship for Famous Best Truck Brake Shims Suppliers – Factory Price Truck BMW Brake Pad 29087 Brake-shoe Block Lining Auto Brake Pad System – Feiying , The product will supply to all over the world, such as: Riyadh, Iran, Rotterdam, Although continuous opportunity, we have now developed serious a friendly relationship with many oversea merchants, such as ones through Virginia. We securely assume that the merchandise regarding t shirt printer machine is often good through a great number of having its good quality and also cost.

We are a small company that has just started, but we get the company leader's attention and gave us a lot of help. Hope we can make progress together!