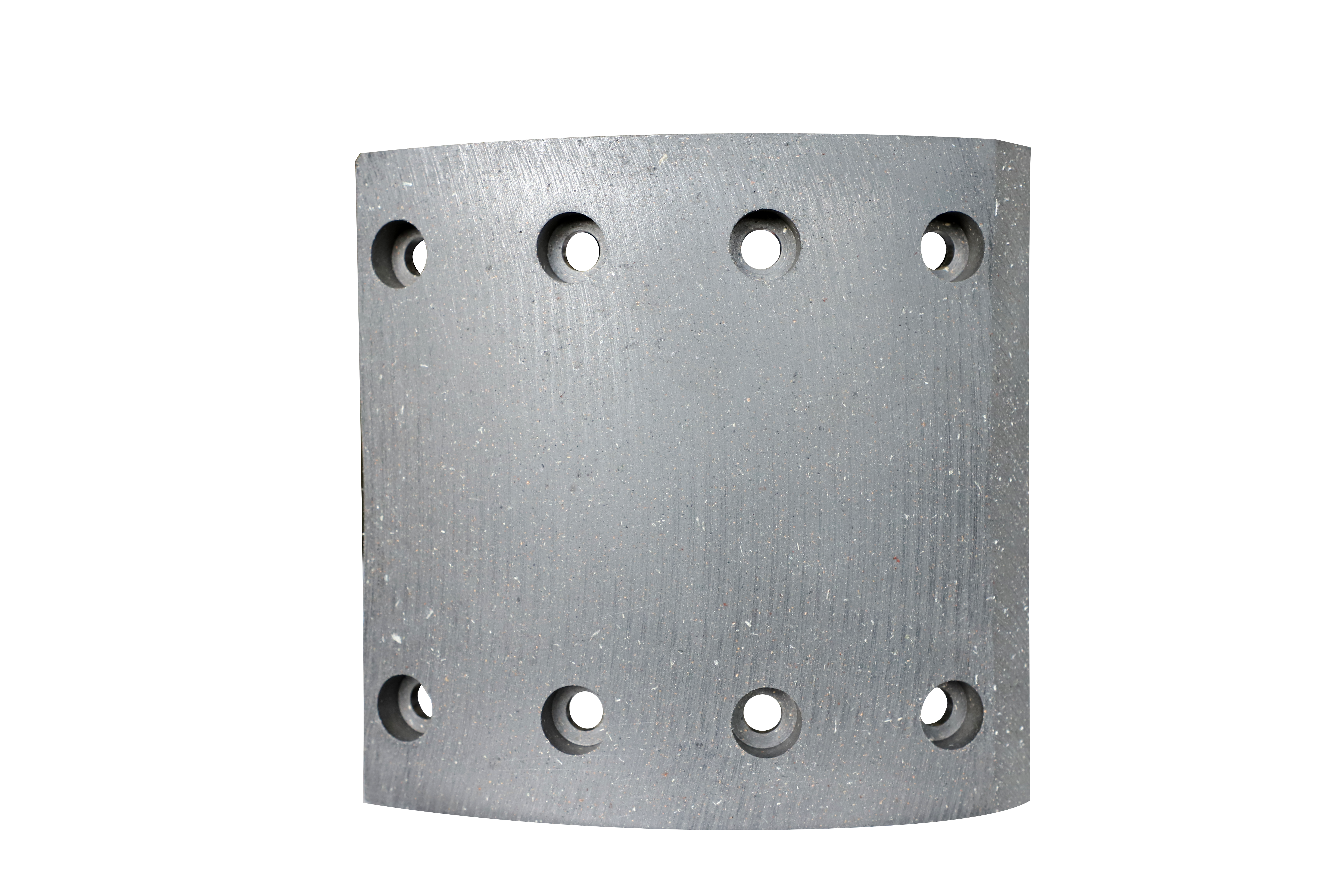

High Quality Brake Lining 19246 for SCANIA / DAF

Failure Analysis

1. Failure: Continuously stepping on the brakes, the pedal return is raised, and the braking effect is improved.

Reason: The gap between the friction plate and the brake drum is too large.

2. Failure: the brake pedal is stepped to the end, the braking effect is not good; continuous braking, the effect is not improved, and the pedal is gradually raised.

Cause: There is gas in the brake system.

3. Fault: the pedal position is very low; pedal again, the position cannot be raised, and it feels hard

Cause: The master cylinder is blocked.

4. Fault: the pedal height is normal, not soft or sinking, but the braking effect is not good.

Reason: The gap between the friction plate and the brake drum is too large or there is oil pollution.

Specification

Name: DT5200/5300

Size: 217.5*107.5*31

Applicable models:/

Remarks: Castings, spring bars and snaps are installed

100% Crucial Dimension, Crack Detection

Complete Models for Different Vehicles

Tens of Different formulation to satisfied to different market

|

Name |

Outer arc |

Inner arc |

Width |

Radius |

Head thickness |

Current thickness |

Center distance |

|

W020-19032 |

220 |

204 |

180 |

203 |

10.5/17.5 |

10.5/17.5 |

130 |

|

W021-19094 |

220 |

204 |

200 |

203 |

10.5/17.5 |

10.9/17.1 |

150 |

|

W024-19581 |

195 |

175 |

222 |

201 |

15/18 |

15.5/18.2 |

92/180 |

|

W025-19582 |

235 |

218 |

222 |

201 |

9.0/18 |

9.2/17.8 |

92/180 |

|

W059-19487 |

192 |

177 |

182 |

200 |

13/17 |

13/17 |

92/140 |

|

W060-19488 |

195 |

177 |

220 |

200 |

13/17 |

13/17 |

92/180 |

|

W071-4551a |

212 |

191 |

219 |

203 |

10.5/18.5 |

11.8/19 |

98.4/177.8 |

|

W072-4551c |

206 |

188 |

219 |

203 |

15.5/18.5 |

15.5/18.5 |

98.4/177.8 |

|

W108-L4705a |

196 |

177 |

177.8 |

185 |

11.2/18 |

11.2/18 |

79.38/136.52 |

|

W109-L4705c |

194 |

171 |

177.8 |

185 |

15.5/18.7 |

15.5/18.7 |

79.38/136.52 |

|

W137-19246 |

201 |

184 |

185 |

195 |

14.5 |

14.5 |

125 |

|

Name(Holes) |

Quantity |

Through |

Large aperture |

Small aperture |

Total |

Segmentation |

positioning |

angle |

|

W020-19032 |

10 |

|

16.5 |

8.5 |

160.16 |

41.09 |

19.67 |

180 |

|

W021-19094 |

10 |

|

16.5 |

8.5 |

160.16 |

41.09 |

19.67 |

180 |

|

W024-19581 |

8 |

|

16.5 |

8.5 |

134.18 |

45.55 |

17.01 |

180 |

|

W025-19582 |

10 |

|

16.5 |

8.5 |

177.43 |

45.86 |

19.19 |

180 |

|

W059-19487 |

8 |

16.5 |

16.5 |

8.5 |

133.8 |

45.38 |

20.4 |

180 |

|

W060-19488 |

8 |

|

16.5 |

8.5 |

133.8 |

45.83 |

20.4 |

180 |

|

W071-4551a |

16 |

|

13 |

6.5 |

139 |

58.31 |

26.5 |

180 |

|

W072-4551c |

16 |

|

13 |

6.5 |

139 |

58.31 |

26.5 |

180 |

|

W108-L4705a |

14 |

|

13 |

6.5 |

126.55 |

53.1 |

25.42 |

150 |

|

W109-L4705c |

14 |

|

13 |

6.5 |

126.55 |

53.1 |

20.98 |

150 |

|

W137-19246 |

8 |

|

18.5 |

10.5 |

139.76 |

47.53 |

13.5 |

180 |

Model Table

|

Category |

No. |

Applicable models |

|

Clutch disc |

80010 |

Adaptation: Shaanxi Automobile Delong*6000 and other 500-580 horsepower |

|

80042 |

Adaptation: Dongfeng Tianlong flagship (small plate), etc., 310-500 horsepower | |

|

80047 |

Adaptation: Foton, Omark and other high-end light trucks | |

|

80076 |

Adaptation: Foton, JAC high-end light trucks | |

|

Clutch pressure plate |

90004 |

Adaptation: Dongfeng, Foton, Sinotruk, etc. 310-520 hp (Universal) |

|

90021 |

Jinlong, Yutong and other buses, XCMG, Weichai, Deutz, etc. | |

|

90044 |

Adaptation: 3 ton forklift (Forklift) | |

|

90069 |

Adaptation: Foton, JAC and other high-end light trucks | |

|

Drum brake pads |

4551 |

trailer |

|

4705 |

trailer | |

|

19032 |

BPW | |

|

19094 |

BPW | |

|

19246 |

Sinotruk | |

|

19487 |

North Benz | |

|

19488 |

North Benz | |

|

19581 |

After Dronman | |

|

19582 |

After Dronman | |

|

Disc brake pads |

5200 |

--- |

|

5300 |

--- | |

|

29087 |

North Benz, Scania, Shaanxi Heavy Truck | |

|

29228 |

BPW | |

|

DA05 |

Delong Bridge, Auman ETX | |

|

We have more than 2000 SKUs |

||

1. Annual production of 35 million pieces

2. Advanced and perfect material formula and front-end quality inspection big data center

3. Possess ISO14001/IATF16949 quality certificate

OE standard, CCC certified

Classification

High Carbon Fiber Brake Pads

This section is dominated by steel fibers and a large number of composite fibers

Fiber-reinforced asbestos-free products.

Features: Steel fiber can improve product crack resistance, impact resistance, wear resistance and corrosion resistance. The composite fiber is a green and environmentally friendly material, which is stable and reduces the shrinkage and expansion of the material to improve braking performance, soft texture, high porosity, and the combination of steel fiber and composite fiber has high strength, long service life, and braking performance. Good, high temperature resistance. Suitable for vehicle use on various roads.

Aramid Fiber Brake Pads

This section is made of aramid fiber and high-quality imported graphite

Products developed for the main material.

Features: The products of aramid fiber and high-carbon expanded graphite have higher strength, better wear resistance, and more stable friction coefficient. At the same time, it also reduces the density of the product and enhances the comfort of the product. It is suitable for use in various vehicle use on the road

Metal Fiber Brake Pads

This section is dominated by steel fibers and a large number of composite fibers

Fiber-reinforced asbestos-free products.

Features: Steel fiber can improve product crack resistance, impact resistance, wear resistance and corrosion resistance. The composite fiber is a green and environmentally friendly material, which is stable and reduces the shrinkage and expansion of the material to improve braking performance, soft texture, high porosity, and the combination of steel fiber and composite fiber has high strength, long service life, and braking performance. Good, high temperature resistance. Suitable for vehicle use on various roads.

Ceramic Fiber Brake Pads

This section is based on glass fiber, mineral fiber-based reinforcing fiber

dimensional products.

Features: It has a stable friction coefficient, as well as high strength, high temperature resistance and wear resistance. It is especially suitable for heavy-duty vehicles on various flat roads and hilly roads.

-1-300x200.png)